The Solar Control System is both the heart and brains of solar water heater. It is what controls the flow of heating fluids and water, based on programmable temperature differential measurements. It measures the temperature in various zones such as at the output of the collectors and compares this to the temperature of the solar storage tank or pool water and makes decision to turn off/on pumps and Diverter valves. The solar controller displays the current status of the system and makes adjustments for optimal performance and safety. It can also remotely connect the system to a user’s PC or iPhone through the Vbus.net web platform.

For more information on remote monitoring click here.

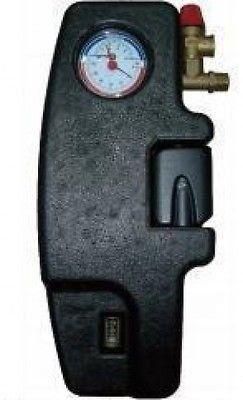

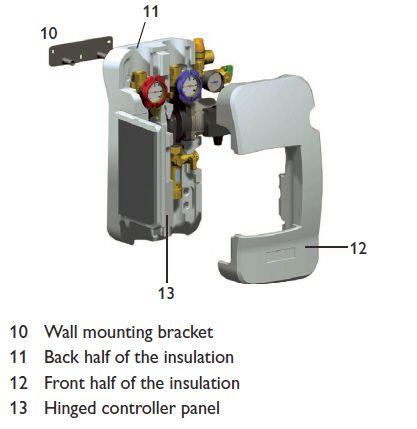

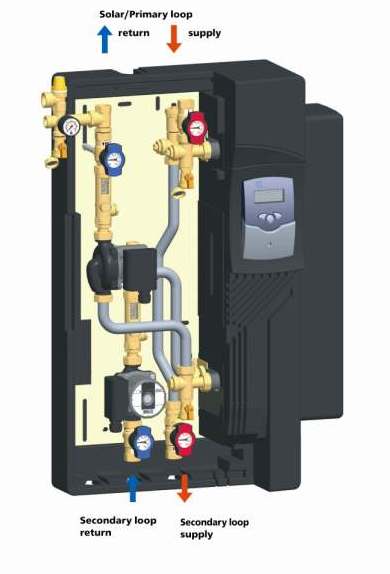

There are 3 main parts to a Solar Control System:

Digital Controller:

This consists of a differential computer that has temperature input sensors and has output relay power terminals. The digital controller will turn the pumps on when there is heat demand from the collector, divert the heat to an auxiliary heating zone if needed and shut the system down if the heat demand is too low (or too high in emergency conditions).